- Gas Generator

- Diesel Generator

- Gas Power Plant

- Spare Parts

- Natural Gas Generator

- Biogas Generator

- Biomass Generator Set

- Diesel Generator Set

- Natural Gas Power Plant

- Biogas Power Plant

- Diesel Power Plant

- Engine Spare Parts

- Gas Engine Generator

- Diesel Engine Generator

- Engine Spare Part

- Captive Power Plant

OEM Precision A380/ADC12/A356/A319 Zinc/Aluminum Gravity Die Casting Part Sand Cast High Pressure Die Casting Part for Auto/Motorcycle/Car Spare Housing

Basic Info

| Model NO. | CEX-01 |

| Die Casting Machine Type | Cold Chamber Die Casting Machine |

| Die Casting Method | Precision Die Casting |

| Application | Auto Parts |

| Machining | CNC Machining |

| Material | Aluminum Alloy |

| Surface Preparation | Deburring |

| Pressure Chamber Structure | Horizontal |

| Tolerance Grade | 6 |

| Casting Surface Quality Level | 1 |

| Certification | CE, RoHS, ISO 9001:2000 |

| Equipment | 200-1100t Casting Machine |

| Surface | Trimming, Deburring,Polishing, Shot Blasting |

| Type of Material | A356.2 |

| Process | Squeeze Casting / Liquid Forging |

| Advantage | High-Strength High Density |

| Description | Aluminum Die Casting Auto Parts |

| Transport Package | Carton |

| Specification | OEM |

| Trademark | CEX |

| Origin | Qingdao, China |

| HS Code | 7616991090 |

| Production Capacity | 1000tons/Month |

Packaging & Delivery

Package size per unit product 35.00cm * 10.00cm * 15.00cm Gross weight per unit product 0.800kgProduct Description

OEM Precision A380/ADC12/A356/A319 Zinc/Aluminum Gravity Die Casting Part Sand Cast High Pressure Die Casting Part for Auto/Motorcycle/Car Spare Housing

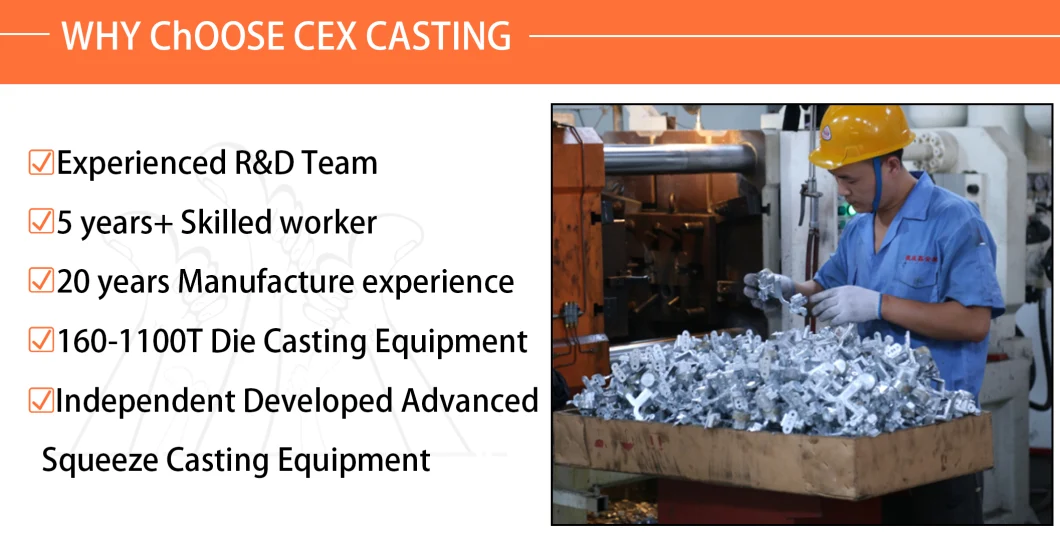

1. 20 Years Aluminum alloy die casting Manufacture Experience. 2.10 Years Export Experience 3. Mould developed by ourself 4. With 160-1100T Die Casting Equipment *9 Set 5.One-Stop Service , Machining --Powder Coating--Assembly service all be available .

Product parameter

| Process | Aluminum Die casting, Squeeze casting+T6, Zinc Alloy die casting,CNC machining, Turning |

| Equipment | Cold chamber die casting machine:200T/280T/400T/600T/800T/1100T.CNC centers, CNC turning, CNC lathes, electrical pulse, line cutting, milling, drilling, grinding |

| Material | A319, A356, A360, A369, A380, A383, A384, A413, A535, 44300, 44300, 46000, AlSi9Mg, AlSi9Cu3, ADC12, ZL102, ZL104, ZL108, Zamak2,3,5,7 ect.Squeeze Casting: A356+T6, A356.2+T6, AlSi9Mg+T6, Zl108+T6, AlTi-Alloy+T6 |

| Surface | Trimming, Deburring,Polishing, Shot blasting, Sand blasting,Tumbling, Powder coating, Anodizing, Chrome, Zinc, Electrophoresis, Passivation, Chemical coating. |

| Software Assistance | Pro-e/Solid work/UG/Auto CAD/CATIA |

| Products Application | Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect. |

Other Assistant Equipment

-Precision CNC lathes-Milling machines-Ultrasonic welding machines-Avarious auxiliary processing machinery.

Product Show

Factory Workshop

Our Certification

Wide Application:

With the current emphasis on reducing materials consumption through virtually net shape processing and the demand for higher-strength parts for weight savings, the emergence of squeeze casting as a production process has given materials and process engineers a new alternative to the traditional approaches of casting and forging. By pressurizing liquid metals while they solidify, near-net shapes can be achieved in sound, fully dense castings.Squeeze casting is simple and economical, efficient in its use of raw material, and has excellent potential for automated operation at high rates of production. The process generates the highest mechanical properties attainable in a cast product. The microstructural refinement and integrity of squeeze cast products are desirable for many critical applications.

Application Range:Packing

FAQ

1. Are you manufacture Factory ?

Yes , we are manufacture factory with more than 20 years manufacture experience and 10+ years export experience .

2. If we don't have drawing, can you make drawing for me?

Yes, we make the drawing of your sample and duplicate the sample.

3. When can I get the sample?

Sample: 15-20days after you start to make mold. The accurate time depends on your product.

4. What is your main order time?

Order time:20-25 days after the payment. The accurate time depends on your product.

5. What is your payment method?

Tooling: 100% TT advanced.

Main order: 50% deposit, balance 50% to be paid before shipment.

6. Which kind of file format you can read?

PDF, ISGS, DWG, STEP, MAX..