- Gas Generator

- Diesel Generator

- Gas Power Plant

- Spare Parts

- Natural Gas Generator

- Biogas Generator

- Biomass Generator Set

- Diesel Generator Set

- Natural Gas Power Plant

- Biogas Power Plant

- Diesel Power Plant

- Engine Spare Parts

- Gas Engine Generator

- Diesel Engine Generator

- Engine Spare Part

- Captive Power Plant

High Alumina Refractory Brick for Captive Power Plant Cfbc Boiler

Basic Info

| Specification | Al2O3 45%-85% |

| Trademark | FM |

| Origin | China |

| HS Code | 69022000 |

| Production Capacity | 12000 Tons/Year |

Product Description

Company profile:ZIBO HITECH MATERIAL CO., LTD is the specialized manufacturer and supplier of refractory in China, Our products mainly include refractory bricks, refractory castable, refractory precast shape, insulating brick etc. For refractory castable and precast shape they are very popular in the Europe, North American area.

HIGH ALUMINA BRICK:

high alumina bricks are produced with selected bauxite chamotte by advanced process and strict quality control. The main mineral components are corundum and mullite phases. It(High Alumina Brick,Alumina Brick,Refractory Alumina) features excellent high temperature mechanics and chemical corrosion resistance.

Type: According to Al2O3 content, the bricks are separated in to types as following :FMLZ-45 FMLZ-50 FMLZ-55 FMLZ-60 FMLZ-65 FMLZ-70 FMLZ-75 FMLZ-80 FMLZ-85

Application:They are widely used in the basic zone of metallurgical furnaces, nonferrous furnaces , regenerator of glass furnaces, power plant circulating fluidized bed boiler etc.Specifications:

| Item Specifications | LZ-48 | LZ-55 | LZ-65 | LZ-75 | LZ-80 | LZ-85 | |

| Al2O3 % | ≥48 | ≥55 | ≥65 | ≥75 | ≥80 | ≥85 | |

| Fe2O3 % | ≤2.5 | ≤2.5 | ≤2.0 | ≤2.0 | ≤2.0 | ≤1.8 | |

| Refractoriness°C | 1760 | 1760 | 1770 | 1770 | 1790 | 1790 | |

| Bulk Density≥ g/cm3 | 2.30 | 2.35 | 2.40 | 2.45 | 2.63 | 2.75 | |

| Apparent porosity % | ≤23 | ≤23 | ≤23 | ≤23 | ≤22 | ≤22 | |

| Refractoriness under load 0.2MPa°C | 1420 | 1470 | 1500 | 1520 | 1530 | 1550 | |

| Cold crushing strength MPa | 45 | 45 | 50 | 60 | 65 | 70 | |

| Permanent linear chang % | 1500°C×2h | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 |

Hitech Material Group is a specialized group in refractory materials and insulation products. The headquarter is named "Zibo Hitech material co., ltd" , which is located in Zibo city, Shandong province. In addition, there are 3 factories under the Group.

Our company mainly develop and manufacture refractory bricks, monolithic refractories and ceramic fibers, which has 5000 m2 machine pressure workshop, 3000m2 the castable workshop, two 86 m and 75 m tunnel kilns, 16 sets of 350 t - 1000 t friction press, 3 sets of automatic batching system.

Hitech passed ISO 9001-2000 international quality system certification, that strictly keep accordance with the approved specification and standard requirements for production and marketing.

In recent years, Hitech has been developing new products constantly, exploring new technologies and new processes and results. Hitech have offered large amounts of refractory products and insulation products for many national important projects, and participate in many domestic and foreign large-scale engineering design and construction.

With advanced production technology, technical equipment, integrated and scientific quality control system, our products are widely used in the field of metallurgy, cement, glass, electricity, oil, chemical engineering, machinery, aerospace, construction.

Hitech Material has been in international exhibition since 2007. Hitech materials are highly commended by domestic and overseas customers with excellent quality, precise measurement and good appearance.

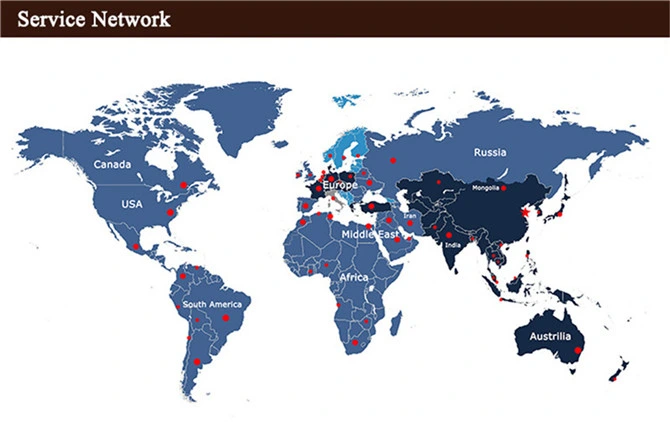

Our products are exported to USA, Canada, Argentina, Spain, Brazil, Mexico, Italy, Germany, Netherlands, Belgium, Turkey, Norway, India, Pakistan, Korea, UAE, Saudi Arabia, Iran, Iraq, Australia etc. Hitech materials are highly commended by domestic and overseas customers with excellent quality, precise measurement and good appearance.

Hitech would like to get your cooperation and support by our exquisite technology, excellent product quality and service. Offering continually high quality service is our unremitting pursuit.

1. How you can control your quality? For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods. 2. What's your delivery time? It usually needs about 20-45 days after receiving the deposit. 3. Do you provide free samples? Yes, we can provide a free sample for testing, If we have sample in stock. The quantity based on the material type, The buyer should bear all the shipping costs. 4. What's your payment terms? We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000. 5. Can we visit your Company? Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend. 6. What standards do we have? Our products meet the standards, such as ASTM, ASME, AMS, DIN, JIS etc. The third party testing is all available for us. For more details, please visit our official website: http://hitechmaterial.en.made-in-china.com