- Gas Generator

- Diesel Generator

- Gas Power Plant

- Spare Parts

- Natural Gas Generator

- Biogas Generator

- Biomass Generator Set

- Diesel Generator Set

- Natural Gas Power Plant

- Biogas Power Plant

- Diesel Power Plant

- Engine Spare Parts

- Gas Engine Generator

- Diesel Engine Generator

- Engine Spare Part

- Captive Power Plant

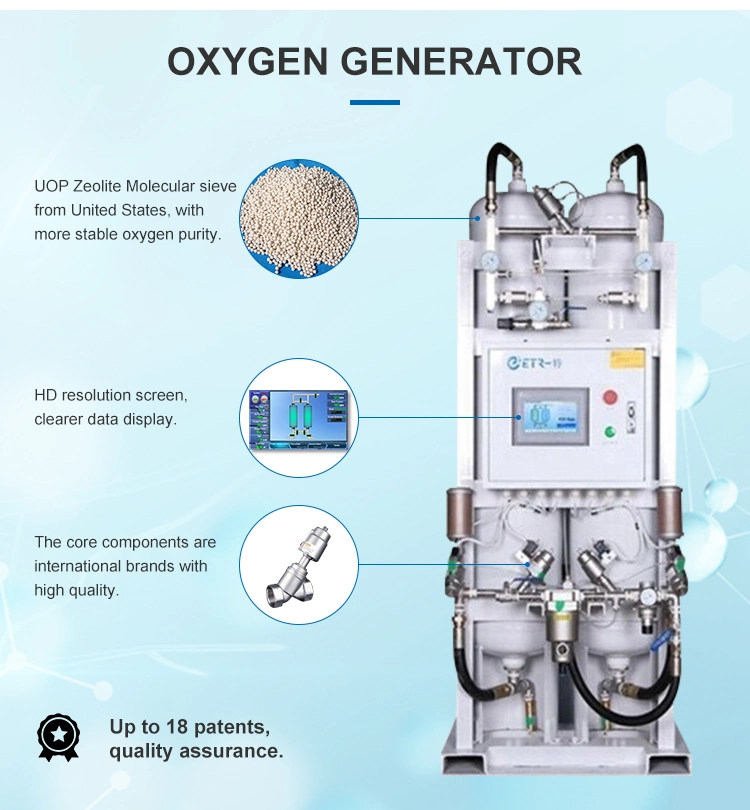

on Site/APP Monitor Hospital Use Medical Psa Oxygen Oxigen Gas Generator with Factory Price

Basic Info

| Model NO. | ETO-10 |

| Certification | ISO9001, CE, ISO13485 SGS TUV |

| Noise Level | Low |

| Voltage | 220; 380V, Customized |

| Purity | 90%-96% |

| Technology | Pressure Swing Adsorption (Psa) |

| Oxygen Capacity | 1-120nm3/H |

| Oxygen Pressure | 4bar/Customized |

| Warranty Period | 18 Month After Shipment |

| Certificate | ISO/Ce/SGS/TUV |

| Power | 60W |

| Name | Hospital Use Medical Psa Oxygen Generator |

| Zms | Uop/China Top Supplier |

| Type | Skid-Mounted |

| Control | on-Site/APP Monitoring |

| Application | Medical |

| Optional | Cylinder Filling Station |

| Transport Package | Wooden Case |

| Specification | Actual size |

| Trademark | ETR |

| Origin | Changsha China |

| HS Code | 8419601900 |

| Production Capacity | 50 Sets/Month |

Product Description

With PSA principles, ETR medical PSA oxygen generator can produce 93%±3% purity oxygen gas directly from compressed air. Compared with traditional Bulk liquid oxygen and cylinders oxygen, ETR on-site PSA oxygen generator can reduce cost down to 50 percentages. Compressed air is purified through the air dryer and filters to a certain level for main generator to work with. Air buffer is incorporated for smooth supply of compressed air thus to reduce fluctuation of compressed air source. The generator produces oxygen with PSA (pressure swing adsorption) technology, which is a time proven oxygen generation method. Oxygen of desired purity at 93%±3% is delivered to oxygen buffer tank for smooth supply of product gas. Oxygen in buffer tank is maintained at 4bar pressure.

| Item | Model | Capacity | Size (mm) | Weight | Power | Connector | |

| (Nm3/h) | L*W*H | (KG) | (W) | Air Inlet | Oxygen Outlet | ||

| 1 | ETO-03 | 3 | 760×750×1850 | 380 | 60 | DN15(G1/2") | DN15(G1/2") |

| 2 | ETO-05 | 5 | 760×750×2200 | 450 | 60 | DN15(G1/2") | DN15(G1/2") |

| 3 | ETO-10 | 10 | 880×780×2400 | 780 | 60 | DN20(G3/4") | DN15(G1/2") |

| 4 | ETO-15 | 15 | 1070×940×2500 | 1080 | 60 | DN25(G1") | DN20(G3/4") |

| 5 | ETO-20 | 20 | 1450×950×2500 | 1260 | 60 | DN32(G11/4") | DN20(G3/4") |

| 6 | ETO-30 | 30 | 1500×1000×3000 | 1680 | 60 | DN40(G11/2") | DN25(G1") |

| 7 | ETO-40 | 40 | 1750×1200×3150 | 2150 | 60 | DN40(G11/2") | DN25(G1") |

| 8 | ETO-50 | 50 | 2000×1350×3300 | 2500 | 60 | DN40(G11/2") | DN25(G1") |

| 9 | ETO-60 | 60 | 2288×1599×3500 | 2900 | 60 | DN40(G11/2") | DN25(G1") |

| Note: Customization is acceptable | |||||||

| Product Comparison | ||

| Name | ETR Oxygen generator | Other Oxygen generator |

| Purity | 93+/-3% | 90+/-3% |

| Warranty | 18 months | 12 months |

| Maintenance | Low (we supply all spare parts without any profit) | It will be about 2. 5times of cost |

| Price | Low price | High price |

1,Nitric oxide and dew point monitoring 4,PSA oxygen plant, buffer tanks:stainless steel (optional) 5,fast delivery time 6,20 years experiences in manufacturing medical oxygen generator | ||

FAQ:

1. Are you manufacturer or trade company?

We are the manufacturer ofMedical Oxygen Plant For Cylinder Filling, founded in 2003.

2. What's the order Medical Oxygen Plant For Cylinder Filling process ?

a. Inquiry---provide us all clear requirements.

b. Quotation---official quotation form with all clear specifications.

c. Printing file--- PDF, Ai, CDR, PSD, the picture resolution must be at least 300 dpi.

d. Contract confirmation---provide correct contract details.

e. Payment terms--- Negotiable.

f. Production---mass production

g. Shipping--- by sea, air or courier. Detailed picture of package will be provided.

h. Installation and commissioning

3.What terms of payment you use?

T/T, L/C etc.

4.How to get a prompt quotation of Medical Oxygen Plant For Cylinder Filling?

When you send the inquiry to us, pls kindly send it with below technical information.

1) O2 flow rate: _____Nm3/hr( or How many cylinders do you want to fill per day(24hours))

2) O2 purity: _____%

3) O2 discharge pressure: _____Bar

4) Voltages and Frequency : ______V/PH/HZ

5) Application: