Category

- Gas Generator

- Diesel Generator

- Gas Power Plant

- Spare Parts

- Natural Gas Generator

- Biogas Generator

- Biomass Generator Set

- Diesel Generator Set

- Natural Gas Power Plant

- Biogas Power Plant

- Diesel Power Plant

- Engine Spare Parts

- Gas Engine Generator

- Diesel Engine Generator

- Engine Spare Part

- Captive Power Plant

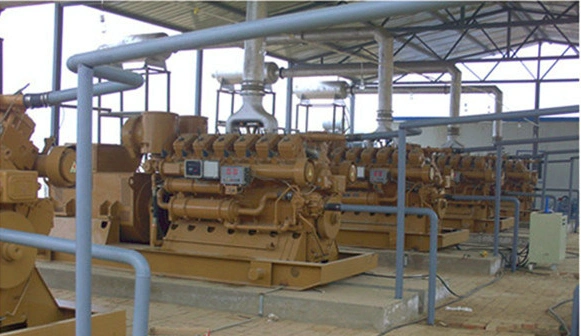

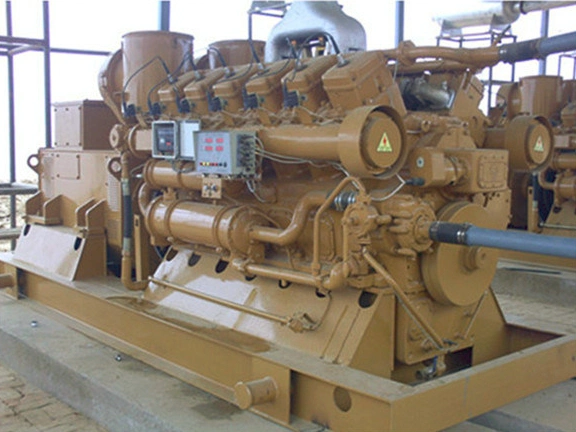

Ce ISO Standard 10-1000kw Natural Gas Generating Set/Electricity Power Plant

Product Description CE approved 10kw-1000kw Natural Gas Generator 1. +20 years professional manufacturer. 2. Wide power

Basic Info

| by Products | Hot Water for Heating House, Hot Steam |

| Gas Pressure | 3-20kpa |

| Lube Oil | Otal Gas Engine Oil 15W-40 |

| Lubrication Mode | Pressure and Splash |

| Warranty | 12 Months |

| Cooling Mode | Closed or Open Type Water Cooling |

| Installation Abroad | Yes, Guide Installation |

| Alternator | Siemens: Brushless, with AVR, Insula |

| Controller | Comap, Deepsea |

| Transport Package | Plywood Case 20/40gp Standard Container |

| Specification | Composition: CH4 |

| Origin | China |

| Production Capacity | 5000sets/Year |

Product Description

CE approved 10kw-1000kw Natural Gas Generator

1. +20 years professional manufacturer.

2. Wide power range: 10kw-5000kw gas generator, single or parallel running.

3. Multi-option of engine, alternator, control system and cooling system, PLC control panel.

4. Long continuous running hours, 8000 hours per year.

5. CE & ISO approved

6. OEM provided

7. Holding many patents

8. Perfect service system(Sales, Installation, Debugging and after-sale service)

9. Full Range: our products mainly include natural gas generator, biogas generator, biomass generator, coal gas generator, syngas generator, coal-bed gas generator, coke oven gas generator, diesel generator etc.

Product Features

Main spare parts:

1.Control system: America Woodward control system

2. Controller: ComAp, Deepsea, Woodward

3. Ignition system: American ALTRONIC, including:magneto, high-tension coil

4. Starting system: DC 24V electric motor.

5. Mixer: IMPCO

6. Spark plug: STITT

Genset worksite requirements

The worksite needs to meet following basic requirements:

a) Ambient temperature between -40ºC~40ºC;

b) Relative humidity less than 95%(35ºC);

c) Site elevation not higher than 3500m;

d) For outdoor installation, simple rain shelter is required.

Requirements for Biogas

Within 1m from pressure regulation valve of gas intake

1. Gas Temperature≤40ºC

2. Pressure 80~200kpa, Changing Rate≤1kpa/min

3. H2S≤20mg/Nm³

4. Content of CH4≥70%

5. Impurity Particle Size≤5μm, impurity content≤30mg/Nm³

6. Moisture Content≤40g/Nm³

Some Tips

Higher content of sulfur and ammonia is not only seriously corrodes the spark plug, but also increase the lubricant's acid value, and then gen-set internal parts will be corroded partly. That will shorten the gen-set's life time. So the gas scrubbing is very important!

Technical Parameters

Parameters for 10-600kw Natural Gas Gen-set

| Parameter of 10-600kw Natural Gas Generator Set | |

| Model Number | LHNG |

| Prime Power | 8-480KW |

| Rated Power | 10-600KW |

| Gas Mixed Mode | Outside |

| Rated Speed | 1500rpm/1000rpm |

| Rated Frequency | 50/60Hz |

| Rated Voltage | 400V/230V |

| Rated Current | 18-1080A |

| Phase | AC 3-Phase, 4 Wire |

| Gas Pressure | 80-200kpa |

| Intake Mode | Natural Intake/Supercharging and Inter Cooler |

| Voltage Stability | ≤±2% |

| Voltage Transient | ≤±10% |

| Voltage Stable Time | ≤1s |

| Heat Consumption | ≤9.8mj/kw.h |

| Lubricant Consumption | 1-1.3g/kw.h |

| Noise | 75-105dB(A) |

| Cylinder Number | 4/6/12 |

| Cylinder Bore | 100/105/135/138/190mm |

| Starting System | DC 24V Electric Motor |

| Sparking Mode | Spark Plug |

| Cooling Method | Circlulating Water Cooling |

| Lubricant Method | Passive and Flying Lubricant |

| Isolation Class | H |

| Protection | IP23 |

| Alternator | Siemens, Standford, Leroy Somer, Marathon, etc. |

| Power Factor | 0.8 Lagging |

| Exciting Method | Brushless |

| Colour | You Decide |

| Certificates | ISO 9001:2008, CE |

| Warranty | 1 Year |

| Overheal Time | More Than 30000h |

| Type | Open |

| Control System | Automatic Alarm System |

| Size | 1450*700*1100mm~6000*1970*2735mm |

| Weight | 600kg~12000kg |

Service

1.pre-sale service:

(1)We will send our engineer to prospect the site of power station free to charge.

(2)According to the situation of site we can supply you many drawings:like power station floor plan,

engineering flow sheet of circle cooling system,genset installation,genset foundation,electrical connection and some other techincal support etc.

2.Sale service:

(1)we will send our engineer to the site to guide you the installation of generator set, subsystem and relative equipment.

(2)We will debug the generator set till it can generate power successfully.

(3)We will also supply a technical training to the operators.Orcan send your staff to our company.We can train you till you can operate the generator set.

3.After-sale service:

(1)Our every engineers are in charge of different area,we will response periodically and support you

technical service free of charge,

(2)For the quality problem, we will service for you free of charge during the guarantee period.

(3)One year guarantee period and lifetime service.

(4)we solve quality problem in time when genset doesn't work,We insure to help our clients to gain the biggest economic profit.

FAQ:

1.How to choose the right model?

A: It depends on real output power, Voltage, Frequency and gas type.

2.What is the oil consumption and capacity per hour?

A: 1.0-1.63g of lubricant oil consumption per hour. 1.0 Cubic meter gas can produce 1.5-3.0kw/h power. The capacity depends on gas energy. E.g 1.0 Cubic meter natural gas produce about 3.0kw/h

3.What is the overhaul?

A: About 30000 working hours. A week is enough to finish.

4. What is the warranty?

A: 1 year. Inside this 1 year, we offer all spare parts free of charge. After this period, spare parts are not free. But, a set of spare parts will be shipped together with machine free.

5. How is the service?

A: We offer installation,repair and maintain service abroad. And online guide service if needed anytime. Our before-sale, in-sale and after-sale service are all trustable, you can name it.