- Gas Generator

- Diesel Generator

- Gas Power Plant

- Spare Parts

- Natural Gas Generator

- Biogas Generator

- Biomass Generator Set

- Diesel Generator Set

- Natural Gas Power Plant

- Biogas Power Plant

- Diesel Power Plant

- Engine Spare Parts

- Gas Engine Generator

- Diesel Engine Generator

- Engine Spare Part

- Captive Power Plant

Syngas Manufacturer Biomass Gasifier Wood Block Rice Straw Peanut Shells Straw Palm Kernel Shell Stove Generator Set

Basic Info

| Condition | New |

| Certification | ISO, CE |

| Type | Fluid Bed/ Fixed Bed Gasifier |

| Model | 10-3000GF |

| Suitable Power | 10-3000kw |

| Supporting System | Gas Purification System |

| Heat Value of Gas | 1100-1300 Kcal/Nm3 |

| Efficiency | ≥75% |

| Feedstock | Wood Chip, Palm Shell, Palm Fibre, Napier Grass |

| Material | Carbon Steel |

| Size | Customized |

| After-Sales Service | Engineers Available to Service |

| Transport Package | Plywood Package by Seaway |

| Specification | 30-3000m3/Hour |

| Trademark | zichai |

| Origin | Zibo, Shandong |

| HS Code | 850220 |

| Production Capacity | 200 |

Product Description

Syngas Manufacturer Biomass Gasifier Wood Block Rice Straw Peanut Shells Straw Palm Kernel Shell Stove Generator Set

The basic principle of biomass gasification system is to convert Agriculture and forestry products and wood processing remains (including rick husks, wood powder, branches, offcuts, corn straws, rice straws, wheat straws, cotton straws, fruit shells, coconut shells, palm shells, bagasse, corncobs,Palm shell, Palm fibre, Napier Grass,Bamboo waste, sawdust, chicken manure and etc.) into combustible gas . It is then used as fuel in gas engine to generate electricity. Biomass gasification successfully conquers the disadvantages of biomass, such as low flammability and wide diversity. Biomass gasification system is characteristic of small land requirement and environment friendly. It's one of the most effective way of biomass utilization.

Comparing with other renewable power generating system, Zichai gasification systerm's characteristic :

1). Flexibility. Gas engine, alternator and even waste heat recovery boiler may be used considering various power plant capacity requirements. It ensures high power generating efficiency. Different capacities of biomass power generation plant can be designed with various types of gasification system.

2). Clean technology. Biomass, as one kind of renewable energy, may reduce the emission of carbon dioxide, sulfur dioxide causing from fossil fuel. Nitrogen oxides emission is very limited in our biomass gasification power generating system because of low temperature (700°C~1200°C).

3). Economic. Gasification is capacity flexible. Even small size biomass power plant is also profitable. Simple process and less land requirements make biomass gasification power plant more economic comparing with other renewable energy. Generally speaking, biomass gasification power generating is the most economic technology in renewable power generating plant, the cost of which is nearly the same as small-size conventional power plant.

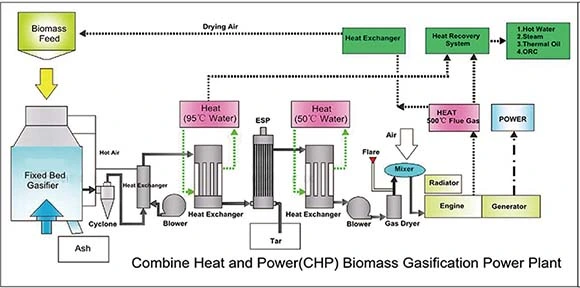

ABOUT CHP

Combined heat and power(CHP) also known as cogeneration, is an efficient,clean,and reliable approach to generate power and thermal energy from a single fuel source. By installing a CHP system designed to meet the thermal and electrical base loads of a facility, CHP can greatly increase the facility's operational efficiency and decrease energy costs. At the same time, CHP reduces the emmission of greenhouse gases,which contribute to global climate change.

The biomass gasification power plant is a biomass system that utilizes the biomass as its energy sources. We have included this section about CHP generally to give yoy a better understanding of this increasing interest and technlogy evolving aound this alternate energy option.

Applicable Fuels

Rice husk, woodchips, sawdust, bark, shavings, crop stalks, coconut hull, olive pomace, bagasse, plastic waste, palm tree, cotton straw. Requirement of the feedstock particle size is ≤2 cm, moisture content ≤20 %.

6MW Woodchip Biomass Power Plant in Croatia

Waste to Energy project, 13x500kW syngas engines running in parallel, synchronized with utility. By using feedstocks of woodchips & rice husks, through biomass gasifier to produce combustible gas fuel, for cogeneration of electricity (for exporting energy) & hot steam (for drying feestocks) & byproducts of biochars, forming a comprehensive energy utilization system.

Project References

Packing&ShippingFAQ1.Are you a trading company or manufacture?Manufacture with factory.2.What kinds of gas generator set do you produce?It covers for all kinds of gas produced in agriculture and industry, including biomass gas, biogas, natural gas, coal mine gas, coke oven gas, semi-coke gas and syngas, as well as related gas produce equipment.3.What is your delivery time?Normally within 60days, it depends on the configuration and quantity, please confirm with us before order.4.What is your payment terms?T/T.5.How do you pack products?Standard export packaging. Equipment packing with plastic bag, and with new solid wooden box, suitable for long-distance sea transportation, moisture-proof, earthquake, rust-proof and anti-brutal handling.6.What is your available port of shipment?Normally Qingdao port, other ports available according to customers' requirement.